EFFiSeal: Exergy for FFplus – Improved Sealing System for Radial Outflow Turbines

Exergy International is a global leader in the development of Organic Rankine Cycle (ORC) systems for power generation from renewable sources and industrial waste heat. ORC technology enables the conversion of thermal energy into electricity using organic working fluids with high molecular weights, allowing efficient exploitation of low- to medium-temperature heat sources—where traditional steam Rankine cycles face both technical and economic limitations.

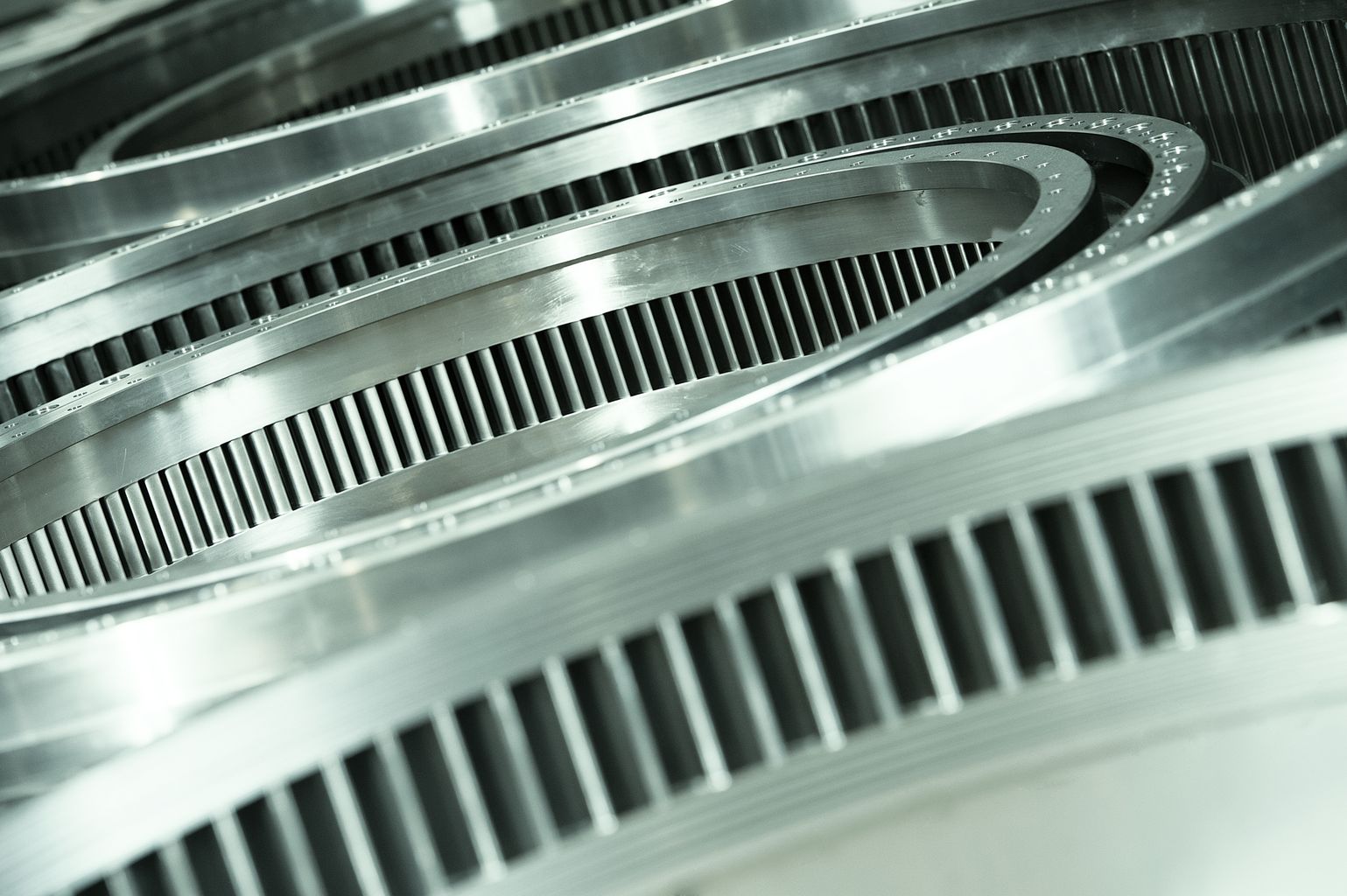

At the heart of Exergy’s technology is its proprietary radial outflow turbine (ROT), a flagship innovation delivering high efficiency, especially in geothermal applications. The turbine’s geometry aligns well with fluid expansion dynamics under low-to-medium enthalpy drops and high volumetric flow rates.

However, Waste Heat Recovery (WHR) applications present a different set of challenges. These systems typically operate at medium-high temperatures with lower volumetric flow rates, a condition that reduces the performance efficiency of radial turbines. To maintain high efficiency under these constraints, a multistage configuration is required. Yet, this introduces increased leakage losses due to more stages and larger seal areas, which significantly impact overall power output.

Why Sealing Matters

In multistage, compressible-flow turbines, sealing losses are a critical performance limiter. The clearances between stator-to-shaft and rotor-to-casing permit bypass flow, reducing effective stage loading and efficiency. Leakage losses scale with both the enthalpy drop and seal surface area, which grow with the number of stages and rotor radius. Minimizing these losses is essential to improve WHR turbine competitiveness.

EFFiSeal Project Goals

The EFFiSeal project aims to investigate and optimise two sealing technologies for use in multistage radial outflow turbines:

- Traditional labyrinth seals

- Innovative brush seals

The primary goal is to validate a high-fidelity CFD-based design methodology that quantifies leakage losses and enables Exergy to identify the most effective sealing approach. A successful outcome will position Exergy more competitively in the WHR market—improving both turbine efficiency and cost-effectiveness.

Technical Approach

Exergy provides the case study and the geometrical models for both sealing configurations. The performance of each sealing system will be assessed across three operating points, allowing the generation of a comprehensive performance curve for both baseline and optimized cases.

Key objectives include:

- Validating Exergy’s 1D internal model of leakage loss using advanced CFD

- Demonstrating performance benefits of brush seals versus labyrinth seals in a realistic WHR turbine configuration

Developing a virtual, multi-stage, periodic turbine model in OpenFOAM including detailed seal modeling and secondary flows

CFD & Optimisation Methodology

The simulation work is driven by EnginSoft, which applies advanced parametric, multi-domain CFD modelling and optimisation techniques.

CFD Model Development:

- 3D turbine flow path parameterisation, including rotors, stators, diffusers, and seal geometries

- Automated, high-quality structured mesh generation for complex radial-axial turbine geometries

- Integration of secondary flows and real gas effects for accurate leakage modeling

Simulation Strategy:

- Development of a response surface methodology supported by a Design of Experiment (DoE) with ~40–50 design points per sealing concept

- Comparative analysis of leakage losses and overall turbine efficiency across multiple configurations

- Use of in-house tools for rapid geometry and mesh creation tailored to rotating machinery

High-Performance Computing (HPC) Support

Due to the computational demands of large-scale CFD and multi-point optimisation, the project leverages LuxProvide’s HPC resources via the MeluXina supercomputing platform. Remote visualisation tools and parallel computation capabilities enable high-resolution simulations and quick iteration over numerous design cases.

Roles and Contributions

- Exergy International provides the turbine design data, internal leakage models, and case study definition, ensuring industrial relevance.

- EnginSoft leads the CFD and optimisation workflow, leveraging deep expertise in turbomachinery simulation and model validation.

- LuxProvide ensures the computing power and technical support needed to run large-scale, CPU-intensive simulations efficiently.

Impact

EFFiSeal will deliver a validated, high-fidelity simulation approach to seal design in ORC turbines, enabling Exergy to:

- Significantly reduce leakage losses

- Improve turbine efficiency in WHR applications

- Accelerate development through virtual testing and performance prediction

- Lower overall system costs and strengthen competitiveness in the growing WHR market

By combining industrial experience, simulation expertise, and supercomputing power, the EFFiSeal project sets a new benchmark for next-generation sealing solutions in ORC turbines.

Learn more about this Business Experiment here.

Authors: Exergy, Enginsoft