High throughput numerical Simulations with HPC and AI for Precision Engineering in welding and Additive Manufacturing

The Current Landscape of Welding and Metal Additive Manufacturing Industry Challenges and the Need for Innovation

The welding and metal additive manufacturing sectors are facing unprecedented challenges that demand innovative solutions. With over a century of accumulated knowledge in welding, combined with the emergence of metal 3D printing technologies such as directed energy deposition (DED) – including wire-arc additive manufacturing (WAAM) and laser metal deposition (LMD) – the industry has reached a critical juncture.

Modern arc and laser welding machines now feature more than 50 interdependent parameters for users to control, creating significant complexity in achieving efficient and compliant welds. This complexity leads to inefficiencies, requiring extensive resources for material and process qualification. The result is time-consuming and costly operations with substantial environmental impacts. Globally, the current approach produces daily emissions of 5,000 metric tonnes of CO₂ and wastes 2,500 metric tonnes of premium alloys solely on parameter testing and process development.

The traditional trial-and-error method of parameter selection is not only resource-intensive but also undermines the potential of advanced manufacturing technologies. Developing accurate numerical models remains difficult and time-consuming, often relying on assumptions that fail to reflect real-world conditions. This process requires highly skilled engineers – expertise that many end-users do not have.

The Role of AI in Modern Manufacturing

Artificial intelligence is transforming the manufacturing landscape by offering unprecedented opportunities for process optimisation and automation. In welding and additive manufacturing, AI-driven solutions can analyse vast datasets to identify improved process parameters, predict material behaviour, and enable real-time process control. This technological shift represents a move from reactive to predictive manufacturing, where processes are optimised before problems arise.

The integration of AI with advanced sensor technologies and high-performance computational resources opens new pathways to achieving consistent quality, reducing waste, and accelerating time-to-market. By leveraging machine learning algorithms trained on comprehensive datasets – incorporating both experimental and simulation data – manufacturers can achieve levels of precision and efficiency that were previously impossible.

3D-Components AS: Leading Innovation in Metal Manufacturing: Expertise and Industry Contribution

Since 2015, 3D-Components AS has established itself as a pioneer in the metal additive manufacturing and welding industry, bringing together expertise in advanced materials, robotics, and AI-driven process optimisation. The company has been at the forefront of developing innovative solutions that bridge the gap between traditional manufacturing methods and cutting-edge digital technologies.

Their core strength lies in developing intelligent systems that understand material behaviour and autonomously select optimal process parameters. This capability has been built through extensive collaboration with leading research institutions and industrial partners, resulting in proven solutions that directly address real-world manufacturing challenges.

Robotic wire arc additive manufacturing process producing layer-by-layer metal structures in an industrial setup. 3D Printed Tooling, Vallourec. (Courtesy: Lincoln Electric).

The company’s strategic partnerships with industry leaders highlight our commitment to delivering practical, industry-ready solutions. These collaborations have enabled us to validate our technologies across diverse industrial environments and ensure that our innovations meet the stringent requirements of critical sectors such as energy, aerospace, and automotive.

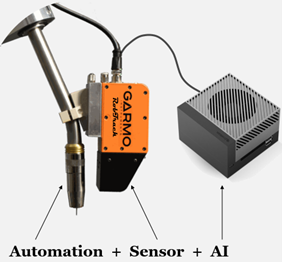

The RobTrack System: Revolutionising Process Parameter Optimisation

At the core of our technological innovation is the RobTrack system, a patent-pending solution that represents a paradigm shift in the control and optimisation of welding and additive manufacturing processes. RobTrack is an AI-driven platform designed to support end-users in screening and identifying optimal process parameters through intelligent experimentation and advanced data analysis.

The RobTrack system integrates a suite of cutting-edge technologies:

- Advanced Sensor Integration – Linear laser profilometry sensors mounted on welding torches provide precise bead geometry measurements with an accuracy of 0.3 mm.

- Edge Computing Capabilities – Local GPU resources enable real-time data processing and AI model inference directly at the point of operation.

- Design of Experiments (DoE) Methodology – Statistical approaches ensure comprehensive exploration of the parameter space while minimising resource consumption.

- Machine Learning Models – Sophisticated algorithms correlate process parameters with material properties and geometric outcomes.

However, experimental execution alone cannot deliver the full range of essential properties—such as displacements, residual stresses, phase distribution, and cooling rates—without the addition of high-end and costly sensors. To overcome this limitation, we have developed a physics-enabled AI approach through the SHAPE-AM project.

The following short video illustrates how the DoE workflow is designed and implemented within the RobTrack software environment.

SHAPE-AM Project: Advanced Process Optimisation Through Physics-Enabled AI

Project Objectives and Technical Innovation

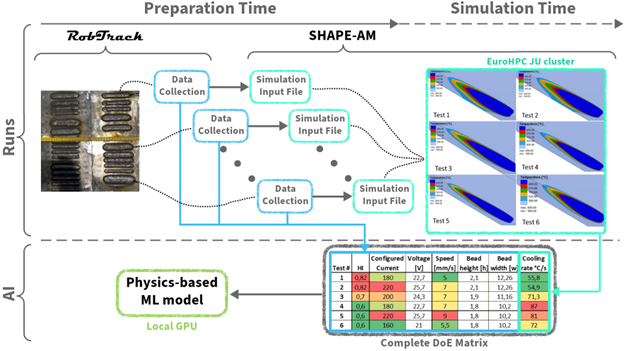

The SHAPE-AM project represents a transformative approach to welding and additive manufacturing optimisation by integrating high-performance computing (HPC) into a cutting-edge workflow for numerical simulations and physics-based artificial intelligence.

The objective is to create highly accurate predictive models that improve welding quality, reduce production costs, and minimise the environmental footprint of metal additive manufacturing and welding processes.

The project’s core innovation lies in leveraging experimentally determined boundary conditions within numerical simulations to produce highly reliable results. This enables the execution of intricate thermomechanical analyses, delivering near real-time insights to AI models and creating a seamless fusion of experimental and numerical data.

Thermomechanical Analysis and Process Optimisation

The thermomechanical analysis capabilities mark a significant advancement in understanding the complex physics of welding and additive manufacturing processes. By applying sophisticated finite element analysis (FEA) models that accurately capture heat transfer, material phase transformations, and stress evolution during production, we can predict critical material properties that are otherwise costly and time-intensive to obtain experimentally.

The thermomechanical simulations utilise advanced mathematical models, including Fourier’s heat transfer equations and the Goldak double-ellipsoid volumetric heat source model, both of which depend on the precise geometry of the weld. These simulations provide invaluable data on:

- Temperature distributions and cooling rates during processing.

- Residual stress development and distribution.

- Material microstructure evolution.

- Mechanical property predictions.

- Distortion and displacement patterns.

By integrating this simulation data with experimental observations from the RobTrack system, we create physics-enabled AI models capable of predicting not only optimal process parameters based on shape and morphology, but also post-process physical and mechanical properties. This comprehensive approach offers end-users unprecedented control over material behaviour and part quality.

Strategic Collaboration with SimEvolution: Advancing Simulation Excellence

Partnership for Advanced FEA Solutions

3D Components AS collaboration with SimEvolution A/S (SIM) is a crucial factor in the success of the SHAPE-AM project. SimEvolution is a renowned Danish engineering firm specialising in mechanical engineering and simulation services, serving as a regional ISV representative for Simufact products and an authorised Hexagon partner.

With over 20 years of experience in structural, thermal, and flow simulations, SimEvolution has extensive expertise in the Simufact product suite. Their deep knowledge of welding simulation software, coupled with close collaboration with software development teams, makes them an ideal partner for implementing automated input file generation and results extraction systems.

Technical Integration and Automation

The collaboration with project partners focuses on several key technical areas:

- Automated FEA Input File Generation – Algorithms are developed to automatically generate FEA input files based on experimental data from the RobTrack system. This ensures that simulation models reflect real-world conditions with high accuracy, while eliminating potential human error in manual setup.

- HPC Integration – Automatically generated FEA files are submitted to an HPC cluster during the DoE stage, enabling high-throughput case solving. This ensures that simulation results are available by the time experimental testing concludes.

- Results Extraction and Processing – Automated systems extract and process simulation results, ensuring that critical data (e.g. temperature distributions, stress fields, and material property predictions) are efficiently captured and integrated into AI training datasets.

- Software Integration – Seamless data flow between the RobTrack data management system and Simufact Welding software enables smooth transfer from experimental observations to simulation setup and results analysis.

Illustration of the SHAPE-AM workflow and interoperability of the solution with the RobTrack system.

High-Performance Computing Partnership with Sigma2, Norway’s National HPC Infrastructure

Consortium collaboration with Sigma2 AS provides essential computational capacity to meet the demanding requirements of the SHAPE-AM project. Sigma2 is Norway’s state-owned national provider of high-performance computing services, representing the country within the EuroHPC JU LUMI consortium and serving as the leading partner of the EuroHPC National Competence Centre (NCC).

Illustration of Sigma2's state-of-the-art data hall at the Lefdal Mine Datacentre.

The computational requirements of our thermomechanical simulations far exceed the capabilities of conventional desktop workstations. For example, a single simulation on a 20-core desktop can take up to three hours. By contrast, utilising Sigma2’s HPC resources with up to 600 cores has the potential to reduce simulation times significantly, bringing them in line with RobTrack’s experimental deposition timeframes.

HPC Implementation and Scalability

The HPC implementation of the SHAPE-AM project involves several key components:

- Scalability Testing – Comprehensive benchmarking across core counts ranging from 200 to 600 to assess the efficiency and scalability of our simulation software on HPC infrastructure. These tests ensure optimal resource utilisation and cost-effectiveness.

- Remote Execution Framework – Integration of HPC workflows into Simufact Welding software, enabling remote execution of numerical analyses, data storage, initial processing, and the transfer of results back to the RobTrack system.

- Cost-Effective Computing – Sigma2’s Category C contribution model for commercial research and industry provides access to HPC resources at competitive rates, making advanced simulation capabilities accessible for industrial applications.

The use of HPC resources enables extensive simulation campaigns to build comprehensive databases that correlate process parameters with material properties. This computational power is essential for training robust AI models capable of reliably predicting optimal process parameters for new materials and applications.

Project Impact and Future Prospects

Transformative Industrial Benefits

The SHAPE-AM project is set to deliver transformative benefits across multiple dimensions:

- Efficiency Improvements – The integration of experimental data with HPC-driven simulations accelerates process development by over 200 times, reducing timelines from days or months to just minutes or hours.

- Environmental Impact – By eliminating trial-and-error approaches, the system could reduce daily global CO₂ emissions by 5,000 metric tonnes and prevent the wastage of 2,500 metric tonnes of premium alloys otherwise used in parameter testing.

- Economic Value – The technology addresses a total addressable market projected at €71.4 billion by 2030, with a focus on robotised welding and additive manufacturing industries growing at a 12% CAGR.

- Quality Enhancement – Physics-enabled AI models provide unprecedented control over material properties, ensuring consistent quality and regulatory compliance across diverse applications.

Market Applications and Scalability

The SHAPE-AM technology has broad applicability across several critical sectors:

- Energy Sector – Oil and gas, nuclear, and wind energy applications requiring high-performance materials and reliable joining processes.

- Aerospace Industry – Lightweight structures and complex geometries demanding precise material property control.

- Automotive Manufacturing – High-volume production requiring consistent quality and reduced development times.

- Maritime Applications – Corrosion-resistant materials and structural components designed for harsh environments.

The brand-agnostic and flexible architecture of the RobTrack system ensures compatibility with existing industrial infrastructure, facilitating widespread adoption without the need for complete system overhauls.

Concluding Remarks

The SHAPE-AM project marks a significant milestone in the evolution of welding and metal additive manufacturing technologies. By combining the experimental expertise of 3D-Components’ RobTrack system, the advanced simulation capabilities of SimEvolution, and Sigma2’s high-performance computing infrastructure, we are establishing a new paradigm for intelligent manufacturing.

The physics-enabled AI approach addresses fundamental limitations in current processes, delivering unprecedented levels of control, efficiency, and sustainability through HPC integration. As the project progresses, we remain committed to delivering solutions that advance the state of the art while providing tangible benefits to industry partners and society as a whole.

The integration of AI, advanced simulation, and high-performance computing in manufacturing represents more than technological progress—it embodies a vision of sustainable, efficient, and intelligent production systems that will define the future of metal manufacturing. Through continued collaboration and innovation, the SHAPE-AM project is setting new standards at the intersection of materials science, artificial intelligence, and advanced manufacturing powered by HPC.

Business experiment presentation here.

Authors: 3D Components AS and SimEvolution A/S