NCC Turkey: Transforming Ideas into Industrial Impact

About TUBITAK and NCC Turkey

The Scientific and Technological Research Council of Türkiye (TÜBİTAK) is the leading agency for the management, funding and conduct of research in Türkiye. Established in 1963, its mission is to advance science and technology, conduct research, and support Turkish researchers. In addition to supporting innovation, academic and industrial R&D activities, TÜBİTAK also develops scientific and technological policies in line with national priorities and manages R&D institutes that carry out research, technology and development studies.

ULAKBİM, an institute of TÜBİTAK, is responsible for operating the national academic network, enabling interaction across the research and development elements of the national innovation system. ULAKBİM aims to provide High-Performance Computing (HPC), High-Performance Data Analysis (HPDA), and Artificial Intelligence (AI) computing and data environment solutions through TRUBA (Turkish Science e-Infrastructure). TRUBA is a high-performance and data-intensive computing infrastructure, offering data and open science services. As the country’s flagship publicly funded e-infrastructure, TRUBA plays a central role in shaping the national computing research and innovation ecosystem, while maintaining strong connections to the European supercomputing landscape.

In the EuroCC Project, TUBITAK ULAKBIM is responsible for coordinating and managing the finances of the National Competence Centre (NCC) of Turkey. The NCC focuses on strengthening industry–academia collaboration through SME HPC case studies, as well as fostering skills development via training events and dissemination activities. Its overarching goal is to integrate the national HPC ecosystem into EuroHPC. TRUBA (Turkish Science e-Infrastructure), the national HPC centre operated by TUBITAK ULAKBIM, provides expertise and HPC resources to the national community.

How NCC Turkey Bridges Academia and Industry

Many SMEs struggle to transform innovative ideas into concrete, fundable experiments. NCC Türkiye addressed this challenge by carefully examining and analysing the call documentation in detail before reaching out directly to potential participant companies. One-on-one meetings were organised, during which every aspect of the call was explained and examples of similar past projects were presented. This approach was designed to demonstrate feasibility, inspire participation, and encourage companies to develop and submit their own proposals. For companies intending to apply, NCC Türkiye provides support at every stage of the proposal process, including supplying the necessary information, clarifying ambiguous sections of the documentation, and guiding applicants through specific requirements.

Through the recently closed FFplus Business Experiments call, NCC Türkiye engaged with a broad portfolio of companies and provided detailed briefings. These were delivered both through one-on-one meetings and online information sessions. As a result of these efforts, NCC Türkiye is aware of at least five companies that successfully completed their applications to the FFplus Business Experiments Call.

TUBITAK Supported the FF4EuroHPC Business Experiment Titled “Better Graphene-Epoxy Based Composite Materials with HPC”

TÜBİTAK played a key role in supporting the creation of the consortium for the FF4EuroHPC experiment “Better Graphene-Epoxy Based Composite Materials with HPC.” The initiative began with Nanografi’s initial contact with METU researchers and advisors, who were already collaborating with NCC Türkiye and TRUBA. During preliminary tests on the integration of HPC into industrial processes, the 2nd FF4EuroHPC Open Call was launched. Recognising this opportunity, NCC Türkiye supported the partners in shaping a consortium that combined complementary expertise.

As a result, Alti Dynamics, an SME with the capacity to coordinate and lead the project, was identified as the technology expert and project leader, while Nanografi took on the role of industrial end user. METU acted as the HPC expert, providing academic know-how, and TRUBA contributed HPC infrastructure, consultancy, and training support. NCC Türkiye facilitated the matchmaking between partners, ensured alignment with the objectives of the FF4EuroHPC 2nd call, and guided the consortium in transforming an initial idea into a well-structured project proposal.

Beyond consortium building, NCC Türkiye provided continuous scientific and technical support throughout the project. In close collaboration with METU experts, TRUBA specialists advised on optimising HPC usage, promoted the adoption of open-source tools such as LAMMPS to reduce reliance on costly commercial software, and trained company staff in running molecular dynamics simulations on HPC resources. This support not only enabled Nanografi and Alti Dynamics to enhance their product development processes but also fostered new know-how and competencies within the Turkish HPC ecosystem.

In summary, NCC Türkiye’s role was twofold: first, to enable effective matchmaking and proposal development; and second, to ensure knowledge transfer and capacity building during the project—laying the foundations for sustainable collaboration between academia, SMEs, and HPC centres.

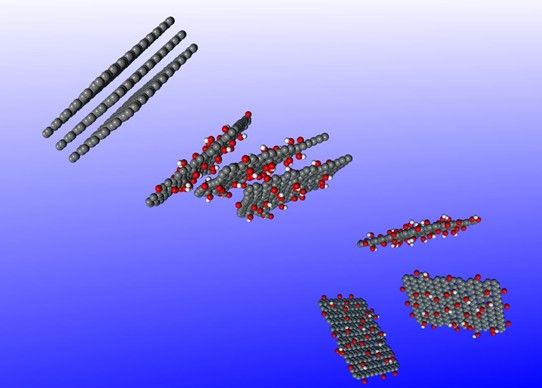

Image 1: To enhance the mechanical properties of polymer–graphene oxide nanocomposites, the dispersion of graphene and graphene oxide nanoparticles is critical, and this can be optimised using HPC resources. Copyrights: FF4EuroHPC project

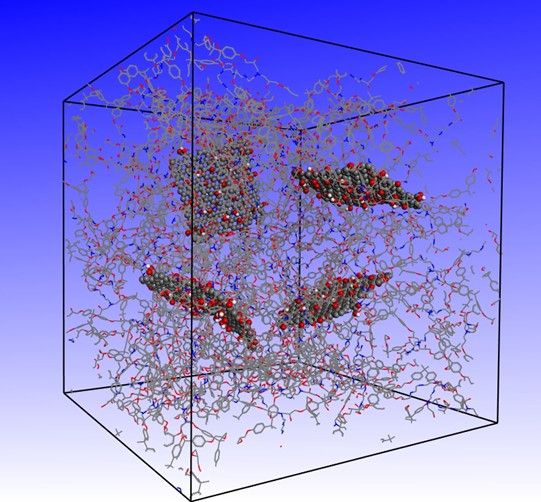

Image 2: Dispersed graphene oxide nanoparticles in the epoxy matrix. Copyrights: FF4EuroHPC project

Industrial Success Story: Reducing Development Time by up to 15% and Costs by up to 20%

Composite materials are formed from a base material—such as a polymer resin like epoxy—and one or more additives that enhance their mechanical, thermal, or electrical properties. In the case of polymer matrix nanocomposites, the improved dispersion and adhesion of graphene additives within the epoxy resin is crucial to achieving these enhanced properties. The key challenge in preparing graphene-reinforced composites lies in obtaining highly dispersed graphene sheets and ensuring their strong interaction with the epoxy matrix.

Pristine graphene sheets are insoluble in most solvents, chemically inert, and difficult to handle as additives in composite formulations. To overcome these limitations, graphene structures can be functionalised with oxygen-containing groups, resulting in a modified nanofiller known as graphene oxide (GO).

The project aimed to optimise these parameters by using computational chemistry methods on high-performance computing (HPC) systems to simulate pathways towards more homogeneous and repeatable manufacturing processes for epoxy/graphene oxide nanocomposites. The targeted application fields included aerospace, automotive, and industrial sectors. The proposed solution combined HPC-based simulations of epoxy/GO nanocomposites with experimental validation: computational chemistry methods were used to model potential improvements in material properties, parameters were fine-tuned based on simulations, and results were validated through the production and testing of samples.

The project involved four partners:

- ALTI DYNAMICS – the lead SME, specialising in advanced aerospace nanomaterial technologies, novel manufacturing processes, and testing systems. As a product designer and manufacturer, Alti Dynamics sought to reduce the high costs and long timescales associated with traditional “synthesise–test–improve” experimental approaches. Since numerous factors influence composite properties—such as epoxy type, graphene dispersion, and pre-treatment conditions—relying solely on experiments often proved expensive and time-consuming. Their objective was to use HPC to accelerate development and obtain optimised, patentable formulations for nanocomposite production.

- Nanografi – a large enterprise and industrial partner, operating one of Europe’s largest graphene production plants with a patented, innovative production method. Nanografi markets more than 1,000 advanced materials, including nanosized graphene and graphene oxide (GO)-enhanced polymer composites. These composites, which already demonstrate superior performance compared to conventional epoxy–graphite composites containing micro-sized aggregates, are used in aerospace and other advanced industries.

- Middle East Technical University (METU) – the academic partner and HPC expert, contributing advanced expertise in computational chemistry and molecular dynamics simulations.

- TÜBİTAK ULAKBİM / TRUBA – Türkiye’s national HPC and data infrastructure provider, supporting academia, industry, and the public sector with high-performance computing resources, data storage, and consultancy.

It is important to note that both TÜBİTAK and METU are also core partners of the National Competence Centre (NCC) Türkiye, which further strengthened the collaborative framework of this project.

HPC experts from METU, in collaboration with infrastructure experts from the HPC centre, implemented an alternative computational route for Alti Dynamics and Nanografi. This approach enabled the modelling of composites using classical molecular dynamics to identify the most promising candidates prior to the synthesis stage. Together with the industrial partners, the team designed a workflow to support the challenging composite-building stage and subsequent analysis, helping to significantly shorten the trial-and-error phases of the manufacturing process.

Through this project, the industrial partners were able to optimise key parameters—such as constituent type and ratio in epoxy–GO nanocomposites—based on theoretical studies performed by the HPC partners. The state-of-the-art in graphene–epoxy composites with enhanced properties was advanced by systematically controlling factors including GO structure, degree of functionalisation, epoxy polymer structure, and cross-linking density. The experiment resulted in the optimisation of GO functional groups and their mass percentage of functionalisation, enabling maximised physical and mechanical properties in epoxy–GO nanocomposites. Crucially, parameters for a more homogeneous and repeatable material manufacturing process were identified, representing a critical outcome for the companies involved.

Business Benefits

Thanks to this experiment, Alti Dynamics is now using HPC-based simulation results to produce high-quality epoxy–graphene nanocomposite materials for a variety of advanced aerospace applications. This approach has reduced development time by up to 15% and costs by up to 20%, thereby increasing competitiveness. The simulations provided optimised parameters for large-scale production and commercialisation, enabling the delivery of improved composites in less time and with greater accuracy. By shifting to a simulation-driven workflow, the companies anticipate reducing testing material waste by 75% and raw material consumption by 30%, significantly lowering the impact of trial-and-error experimentation. These new HPC-enabled capabilities provide Alti Dynamics with a competitive edge and an expected increase in revenue.

Nanografi will also benefit substantially: the company will be able to sell significantly more raw graphene products to customers, particularly in the automotive and aerospace sectors, due to the optimisations achieved through Alti Dynamics’ performance testing studies combined with HPC simulations. This represents a highly profitable advancement for both companies. Furthermore, the successful commercialisation of the project outcomes will strengthen graphene’s position in the composites market as a high-performance, weight-reducing additive.

The companies also gained valuable experience in engaging with HPC solutions for nanocomposites, building new technical capabilities that have led to novel product development. Active utilisation of HPC enhanced the firms’ knowledge base, while the acquisition of new skills during the experiment enabled Alti Dynamics to reduce development times for new nanocomposites and position itself for entry into new market sectors.

The experiment successfully combined technical achievements with tangible commercial benefits for all participants in the value chain, from the industrial user to the HPC centre. The HPC centre proved to be an essential resource for understanding complex material interactions and translating this knowledge into practical applications.

METU made a significant contribution to the project, leveraging its academic expertise to define the crucial link between advanced materials science and molecular-level HPC simulations. In parallel, NCC Türkiye demonstrated its strong commitment to supporting high-tech innovation by providing technical guidance and coordination.

Together, these efforts generated substantial technical and commercial benefits across the consortium, reinforcing the value of close collaboration between industry, academia, and HPC centres.

Addressing technical challenges, unexpected roadblocks in simulation, model tuning, or data handling

This experiment demonstrated the value of HPC calculations for understanding complex material interactions and positioned the HPC Centre as a critical resource for advanced materials research and development. Four partners worked together across different sectors to develop optimized composite recipes with enhanced properties, including higher strength and reduced weight. Molecular dynamics (MD) simulations via HPC were conducted to optimise parameters for epoxy/Gr-GO nanocomposites for these next-generation formulations.

At the start of the project, both METU and TRUBA had limited understanding of industrial synthesis and production processes, while Nanografi and Alti Dynamics had little experience with HPC-based MD simulations. Although METU has a long history of industrial collaborations, integrating an HPC centre into this type of partnership was a first for the university. Similarly, it was the first time that the companies collaborated directly with an HPC centre alongside their usual university and industry partners.

Because the partners initially lacked clarity on the technical information required by others, numerous meetings and communications were held to exchange essential data. For example, METU requested detailed molecular-level information on the nanocomposite system—including chemical structures, crosslinking ratios, molecular weights, and aspect ratios—to create accurate computational models, which was new to the industrial partners. Once these technical data were acquired, HPC simulations began reproducing experimental results, which in turn guided the subsequent experimental studies.

Setting up realistic nanocomposite systems in silico proved to be a challenging task. Difficulties arose in achieving the exact experimental cross-linking ratios and other structural details of the graphene oxide (GO) surface when constructing molecular models of cross-linked polymer resins, as anticipated. Instead of using a single GO structure, multiple random GO sheets were generated, closely matching experimentally determined structural parameters by carefully controlling the type and number of functional groups. The oxygen content of each GO sheet was maintained within the experimental range during modelling.

Achieving the exact cross-linking density of the epoxy resin at the experimental level posed an additional challenge during the early stages of the project. HPC experts at METU employed new-generation software capable of generating epoxy resins with accurate cross-linking density, which also provided a direct interface with the LAMMPS software used for MD simulations. To validate the model system, more than one simulation cell with the same cross-linking density was constructed, and simulations were conducted on each cell.

At the beginning of the project, discrepancies were observed between the experimental and computational mechanical properties of both epoxy resins and epoxy/GO nanocomposites. To address this, the team optimised simulation parameters, including cell size, simulation time, force fields, and other variables, to align the simulated density with experimental values. Additionally, the number of simulated cells was increased to remove highly divergent results from the experimental averages.

Overcoming these challenges had a substantial impact on the project objectives. Firstly, it enabled more accurate molecular modelling of cross-linked epoxy resins, allowing high-precision predictions of the real-world performance of epoxy/GO nanocomposites, representing a significant advancement in the development of superior materials. Secondly, the harmonisation of computational mechanical properties with experimental data significantly increased the reliability and accuracy of the project results. Finally, simulations of different graphene distributions and aggregates provided crucial insights for optimising nanocomposite performance, enabling the production of materials tailored to specific applications in aerospace, automotive, and electronics sectors.

Thanks to the resources provided by TRUBA, data handling throughout the simulations posed no issues.

Advice to other SMEs that haven’t yet explored the use of HPC and AI in their business

For SMEs new to HPC and AI, the key advice is to take the first step, even on a small scale. These technologies can drive innovation, reduce costs, and create new opportunities. Collaborating with competence centres such as NCC Türkiye provides the guidance and infrastructure needed to unlock their full potential.

Learn more about the NCC Turkey here.

Author: Erol, Yıldırım, Assistant Professor, Middle East Technical University